For most businesses, the most cost-effective solution will be metal core printed circuit boards with an aluminum base. You get good rigidity and thermal conductivity at a more reasonable price. For this reason, you can usually aluminum core or copper base.

The reason metal core PCBs are so much more effective at dissipating heat than FR4 boards is due to their thermal conductivity dielectric material, which serves as a thermal bridge from the IC components to the metal plate, automatically conducting heat through the core to a heat sink. If you have FR4 boards, you must add a topical heat sink to transfer heat through the board or it will create potentially damaging hotspots.

In addition to preventing hot spots, a metal core PCB’s thermal conductivity properties also result in less thermal expansion and, as a result, greater dimensional stability. Thermal expansion can cause different layers of the board to take on different shapes or sizes, affecting the integrity and functionality of the board. Protection from thermal expansion is desirable.

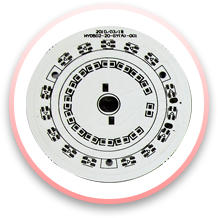

Single Sided LED Aluminum Base PCB

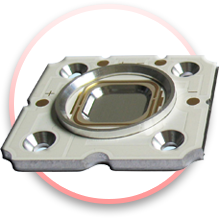

SinkPAD MC PCB

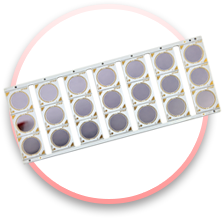

Single Sided COB LED

Single Sided LED Aluminum Base PCB

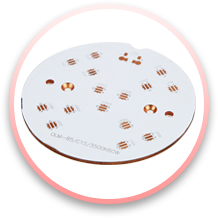

Single Sided LED Copper Base PCB

Printed Circuit Board (PCB) | Flexible Circuits | Rigid Circuits | MC PCB | PCB Assembly | Components Procurement